Introduction

The start of a new year symbolizes a fresh start for most of us. This year, extend your resolutions into your work place. Unfortunately, falls are still the leading cause of injury and death for those working at heights. In addition, OSHA’s number one violation in 2018 was fall protection in construction. These statistics are proof that not enough is being done to prevent falls while working at heights in the work place. However, you can change that in 2019. Read our top 10 fall protection tips and learn how you can keep yourself or your workers safe while working at heights.

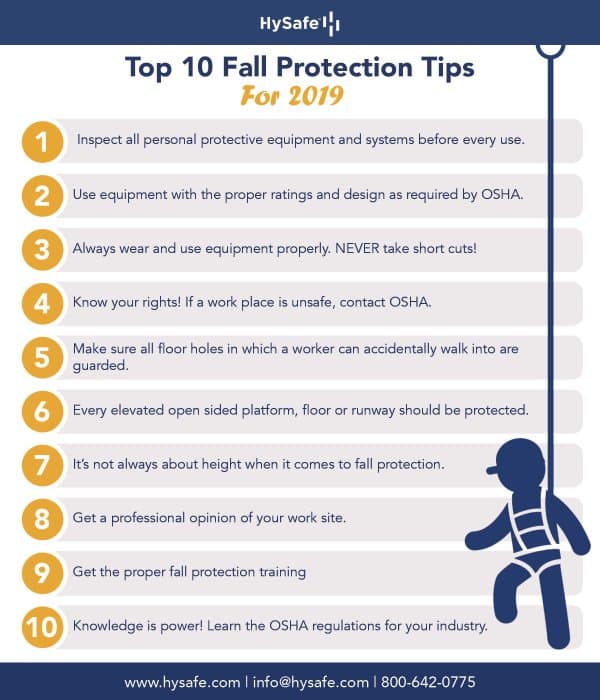

Top 10 Fall Protection Tips For 2019:

1. Inspect all personal protective equipment and systems before every use.

Here’s your first fall protection tip: Do NOT use any equipment that looks frayed, torn, or defective. Without inspecting your fall protection, such as harnesses and lanyards, you’re taking a risk that may cost your life. Be sure to always take an extra few minutes each time you prepare to work at heights and inspect your fall protection equipment.

2. Use equipment with the proper ratings and design as required by OSHA.

Wearing personal protective equipment and using fall protection systems that aren’t properly rated or designed for the forces that are incurred during a fall will cause serious injury or death. Using equipment that isn’t rated and designed properly, is equivalent to not wearing any fall protection at all. Remember, keeping costs low are important but never at the expense of someone’s life. Instead, purchase your fall protection equipment through a credible and reliable company with years of experience to ensure the best possible equipment is being designed, installed and used properly.

3. Always wear and use equipment properly. NEVER take short cuts!

One of our biggest fall protection tips: It may be easy to take the quicker route and improperly wear a harness or disconnect from a lifeline but doing the bare minimum can and will cause more issues in the end. Always work like you could fall at any moment. Keeping this thought in mind can change your perspective next time you wear a harness, connect to a lifeline or step up on any dangerous platform.

4. Know your rights! If a work place is unsafe, contact OSHA.

Under the Occupational Safety and Health Act of 1970, employers are required to provide a safe work place for employees. If your work place is unsafe, contact OSHA at 1-800-321-OSHA (6742), TTY 1-877-889-5627.

5. Make sure all floor holes in which a worker can accidentally walk into are guarded.

It’s easy to forget about holes on the floor when your busy working. Sometimes workers find themselves busy looking at the work that’s directly in front of them and forget to take a quick glance at the floor. Without a floor hole cover, such as a skylight gate or industrial netting, you’ll be taking a large risk.

6. Every elevated open sided platform, floor or runway should be protected.

Be sure to protect workers from unguarded platforms, floors, or runways. Whether your equipment is temporary or permanent, be sure workers are fully protected. Guardrails and lifelines are effective and simple ways to protect elevated open sided platforms, floors, and runways.

7. It’s not always about height when it comes to fall protection.

Fall protection is not only applicable when working at high altitudes but it’s also required when working above dangerous machinery and equipment, regardless of height. For example, if a worker can fall into a vat of acid or onto a conveyor belt, then guardrails and toe-boards should be present to help prevent workers from falling and getting seriously injured.

8. Get a professional opinion of your work site.

Another fall protection tip: It’s nearly impossible to identify all fall hazards without a professional. A quick site visit or full OSHA-approved assessment will give you and your team the peace of mind you need. Getting a professional involved will help you get a better understanding of all the posed risks as well as recommended solutions at your work site.

9. Get the proper fall protection training.

At HySafe, we can’t stress enough how important fall protection training is. Without proper training, you risk improperly using or wearing equipment such as harnesses, lifelines, and lanyards. Once your fall protection system is in place, schedule a training session for both managers and workers to learn the basics of fall protection, how to manage equipment, and how to properly perform a descend and rescue operation. It doesn’t stop there, be sure to schedule training on a yearly basis to refresh minds and even introduce fall protection to any new workers and managers. Basic training approved by OSHA include the Competent Person Training (16 Hours) and the Authorized Worker Training (8 Hours).

10. Knowledge is power! Learn the OSHA regulations for your industry.

Understanding the full scope of fall protection requirements in your industry can go a long way. Whether you are a worker, manager, or somewhere in between, it’s important that you understand what OSHA requires for your work site. Check out OSHA’s requirements for each industry below:

Interested in getting a price for your fall protection needs? Submit the form below to get your FREE quote!

Source: www.osha.gov